This is the second part in a feature series aimed at exploring brine and its role in ion exchange processes. In this second portion, we will take a look at cation exchange operating capacities, capacity vs. salt, and high efficiency systems.

Over the last 30 years, there have been a number of advancements in treatment technologies that have lead to high efficiency softeners. These advancements are a result of high capacity cation exchange softening resins, demand-based regenerating control valves, and a conscious understanding on the impact of salt based regenerating water softeners on local and regional water supplies. In the Great Lakes, Midwest, and Western United States, the demand and pressure on groundwater systems is greater than ever and will continue to rise. Nationally, water conservation and brine discharge are now regulated by state governments across the country.

Previously, we explored the role of salt in brine creation and the kinetics of brine in the regeneration process. Let's take a look at the operating capacities of cation exchange water softeners and brine concentrations. Water softeners are judged primarily by their "salt efficiency," and efficiency is based on its operating capacity between regenerations. As we know, the current marketplace for residential water softeners is filled with high efficiency systems that claim to use less salt and water than older systems. Achieving high operating capacities from cation exchange resins is measured by the capacity of an ion exchange resin versus the concentration of the regenerate solution, based on various salt dosages. Generally, a clock based softener operating at full salting or 15 Lbs. of salt used per regeneration can expect to achieve high capacity between regenerations, but will use significantly more salt over the life of the unit. Clock based softeners are set to regenerate at a set time and date, regardless of whether or not the softener has exhausted the resin's capacity. This scenario is obviously not ideal for a few reasons. First, the system is regenerating regardless of its remaining capacity. If the system has not been fully exhausted, excessive salt is used during brining, and will not contribute to the regeneration process. On the other hand, during periods of heavy water use, these systems could fully exhaust their capacity before regeneration, and result in hardness leakage during service. The majority of high efficiency softeners on the market today use between 3-7 lbs. of salt per cubic foot of resin, and used demand based control valves. These valves measure the volume of water used, through a flow meter, so that the system is only regenerating when needed. Lower salting dosages and demand-based softeners reduce salt consumption and send less salt to drain during regeneration.

There are a number of factors that affect the capacity of a softener and the amount of salt used per regeneration. Designing a high efficiency softener involves finding a unique balance between the capacity of the resin, the amount of salt used per regeneration, and the brining flow rates. Our Satin Series Water Softeners are NSF/ANSI44 tested and certified by the Water Quality Association. To meet this standard, the system must meet the following criteria:

- Proof that your product is safe to use and materials, structural and performance claims are validated.

- Demonstrate that your product meets California efficiency requirements of 4,000 grains per pound of salt.

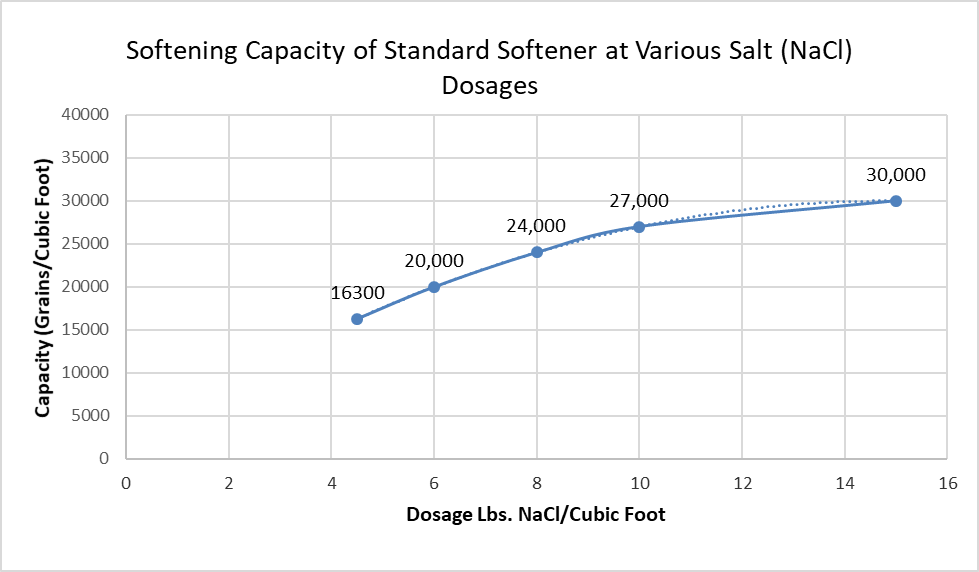

Standard softener designs achieve much lower capacities per pound of salt because of their design. A bottom distributor with gravel, low capacity resin, faster brining flow rates, and lower water-efficient control valves all contribute to lower capacities. The table below illustrates the operating capacity for a standard softener. Dosing at 4.5 lbs. of salt yields a total capacity of 16,300 grains per cubic foot of resin, or 3,622 grains of hardness removed per pound of salt. During regeneration, the gallons to drain for a standard, 1 cubic foot softener can be anywhere to from 60-70 gallons.

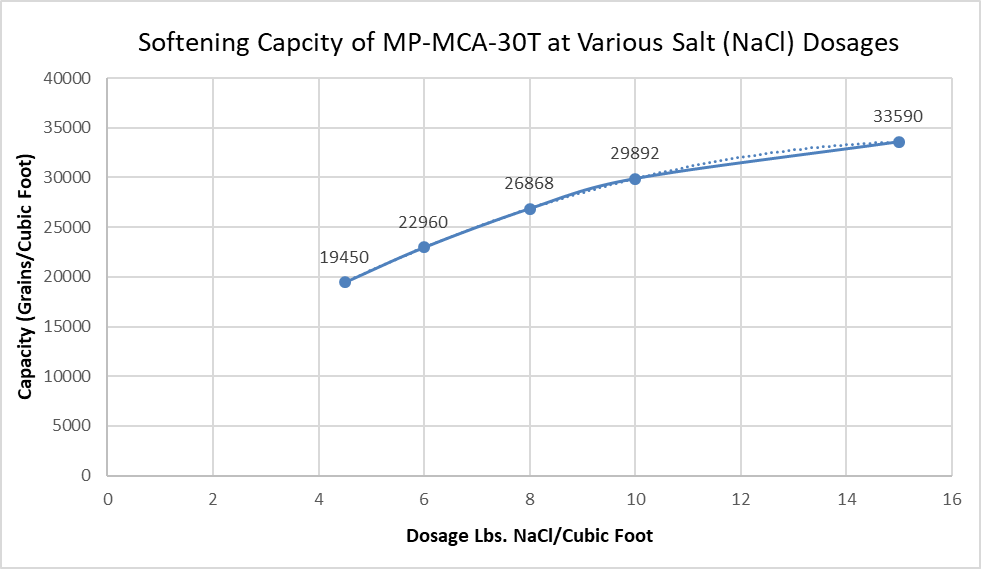

The Master Water Satin Series MP-MCA-30T has a much higher capacity and exceeds the NSF/ANSI 44 standard. Dosing at 4.5 Lbs. of salt yields a total capacity of 19,450 grains per cubic foot of resin, or 4,322 grains of hardness removed per pound of salt. The table below illustrates the capacity achieved at different salting dosages for a Master Water Conditioning Satin Series MP-MCA-30T. During regeneration, the gallons to drain is about 42 gallons. Comparing the two systems, the Master Water Satin Series MP-MCA-30T has a water savings of 40% and is 19% more salt efficient. Our Satin Series Softeners are able to achieve higher capacities because of few a few unique design features. First, our proprietary Clack Valve precisely measures water use, uses less water during regeneration, and a regeneration cycle that uses carefully designed flow rates and duration. Second, we use Vortech plate technology, which provides a larger surface area at the bottom of the tank than a standard distributor, provided more uniform flow characteristics, increasing the realized capacity of the resin. The Vortech plate also results in greater bed lift during regeneration, and a swirling action that more effectively backwashes and rinses the softening resin. Finally, we use Aldex C-800 high-capacity cation exchange resin in all of our softeners.

From both tables, we can see that the relationship between capacity and salt dosage is not linear. In other words, increasing the salt dosage will not increase the capacity of the softener by the same factor. Now some water softener manufactures use 3.5 Lbs. of salt per regeneration as opposed to 4.5 Lbs. of salt. If we extrapolate and compare the data for a Satin Series MP-MCA-30T at 3.5 Lbs of salt, our system could achieve an even higher operating capacity per pound of salt than at 4.5 Lbs. Depending on flow demands, influent hardness levels, and the presence of iron or manganese, the most appropriate salt dosage may vary. One other factor that will affect the efficiency and capacity of a water softener is temperature. During periods of extreme cold or winter months, the colder, denser water can negatively impact the kinetic affects of the brine during regeneration and reduce resin capacity.